Quote from: Striker1423 on May 18, 2021, 03:59:03 PM

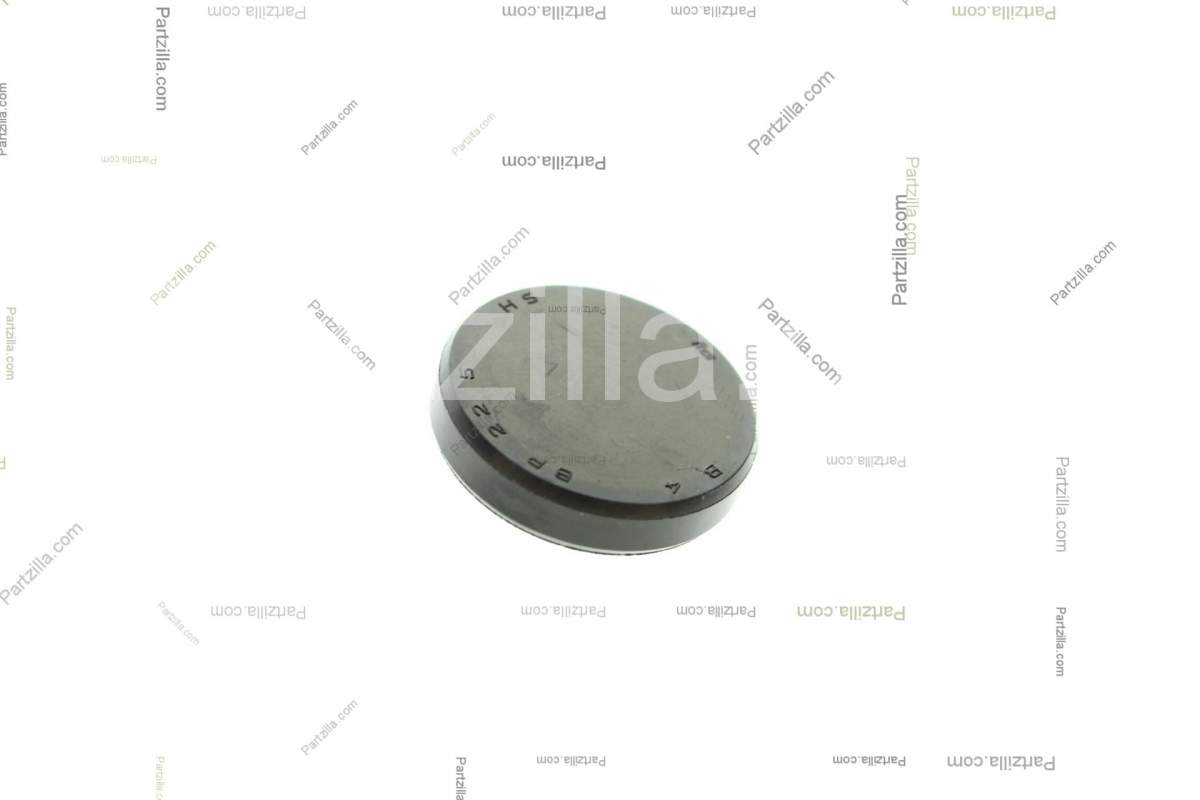

The Carb Windows and dots on the slides are there to sync them when lined up in the middle of the window. Not the bottom of the window.

Is this one of those situations where the manuals are giving bad advice? The Haynes and Yamaha Workshop both say bottom of window, but I imagine the more important thing is that they're even.